Quality control

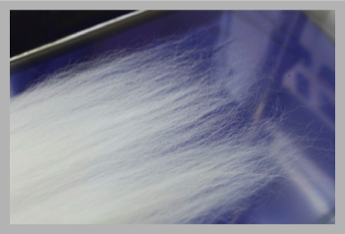

Natural, or synthetic fibers are carefully selected for the rovalrolls filling materials acccording to criteria such as morphology, molecular weight, breaking strength etc.)

Pilot calender (400 KN/m, 30 Hertz) enables the testing and validation of the selected fibers.

The fiber raw materials are validated and contolled on state of the art test equipment in the Roval laboratory : fiber morphology in terms of length, width and specific weight ; length of cellulose chain / degree of polymerisation, mechanical strength properties of fibers.

Process parameters such as cover material moisture content, interference fit and density are calculated according to the cover material properties and the calender running conditions. These key parameters are continually controlled throughout the production process, allowing instant correction of any out of tolerance. In this way the filled roll is guaranteed without defect, and the uniformity of the linear load profile in the calender nip is assured.

The initial fiber selection and control in the laboratory is critical to maximise the performance of the cover. This approach, which is identical for all rovalrolls covers, ensures the identical performance of every cover and helps to maintain the consistency of your calendering process.